3d Printing

Using the latest 3D printing technology, SOS Industrial can turn your digital designs, or design concepts into reality. Just send us your design or technical drawing for a quotation.

3D printing allows for rapid prototyping, fabrication of complex plastic parts, and the ability to make limited production runs without incurring large tooling charges.

Materials

As standard SOS offer a printing service in PLA, PLA+, PETG, ABS and UV Cured Resins. Other specialist materials (such a flexibles) can be used on request. Materials come in a range of colours to suit the requirements of the finished product.

The 3D printing Process

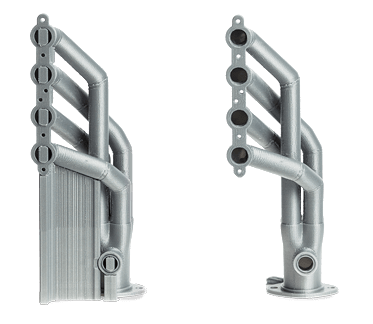

The 3D model of the object is “Sliced” into thin layers, which the 3D printer builds up, from the build plate, layer upon layer. Where there are overhangs or steep angles, sacrificial support material is used, as the printer is unable to print on thin air. This support material is then removed in post production processing, revealing the 3D item. This form of printing is called. Additive Fabrication or AF.

3D files can be printed at different layer heights, from as small as 0.04mm up to 0.5mm or higher. Smaller layer heights give far better definition and surface finish, but take significantly longer to print. 3D objects can also have varying levels of infill (the density of material making up the internal structure of the piece) ranging from 0% to 100%. An item with 0% infill, is essentially just a hollow shell, and would have very little structural strength, whereas an item with 100% infill will be a solid block of the printing material, offering the maximum strength, but also the highest weight and longest printing time.

SOS can advise on the optimum combination of material, layer height and infill density, based on the object to be printed, and its end use.